A Magnetically Coupled Centrifugal pump is suitable for all applications where a sealless pump and/or an leak free design is necessary. Traditionally these applications are for conductor plate, electroplating industry, etching processes or where ever chemical aggressive fluids have to be handled.

The sealless design also plays a role where pressure within closed system is above or below ambient pressure. I.e. Evaporation at the heat exchanger.

And of course these pumps are considered to be maintenance free, which is important when pumps are needed 24/7.

Here are the top 5 benefits of using a Magson Pump:

- Material ETFE is suitable for almost every fluid – it doesn‘t matter if it is acidic or alkaline

- Short deliveries are realized with a modular design – therefor all standard MAGSON pumps are available within 1-2 weeks

- All MAGSON pumps Module BG4 or higher are delivered with hose flange and also a thread adaptor without extra price or longer deliveries!

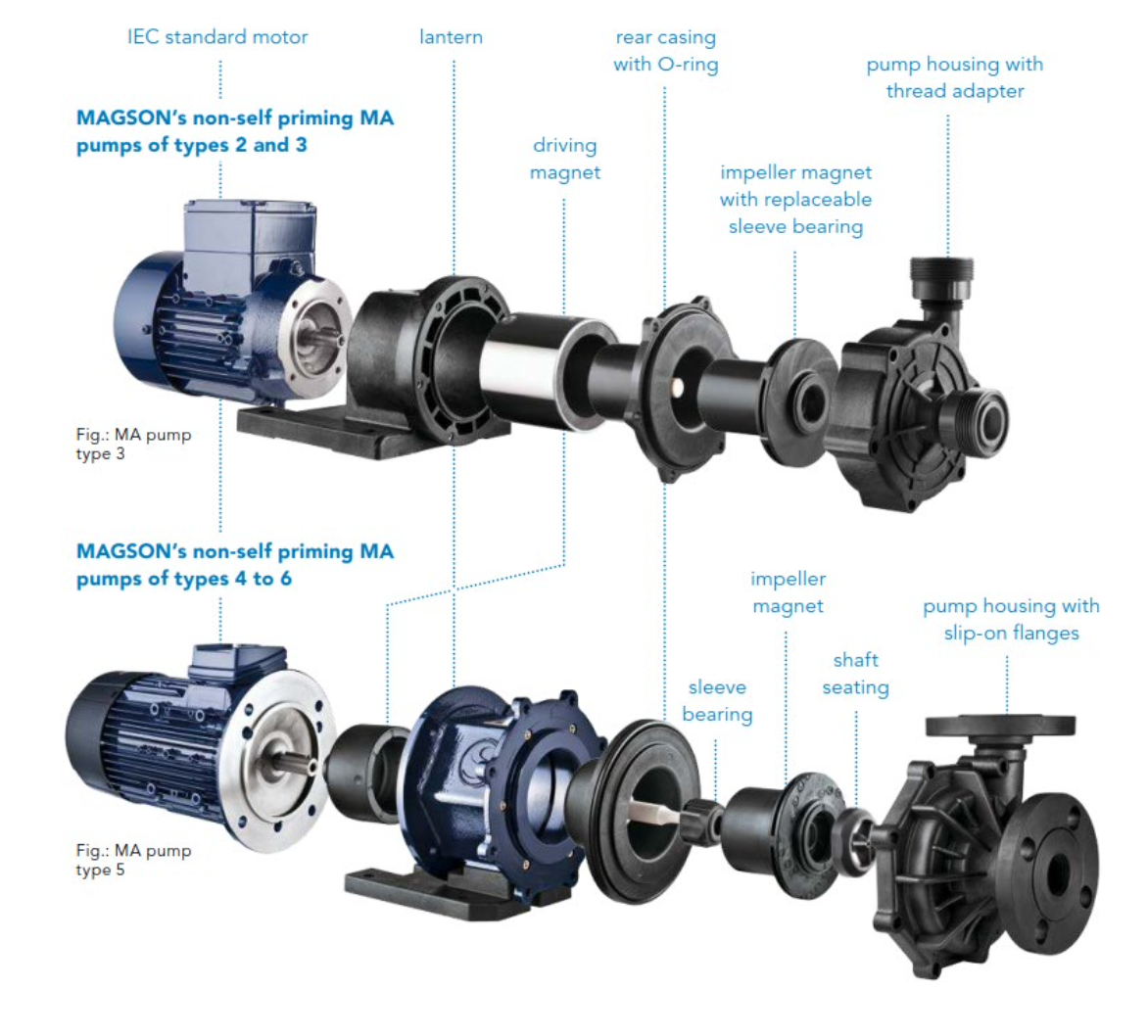

- A big advantage is using IEC-motors as standard execution. Advantage for the customer is a higher availability of the motor at the local market and all motors following IEC can be mounted (i.e. IE4, synchronous motor, etc.). As standard all motors are supplied with PTC or thermal protection. – IE3 is also standard starting with 0.75 kW.

Magson Magnetic Drive Pumps are under the Flux brand of pump and supplied out of Germany.

For more information on this range and its applications you can contact us on info@acufill.co.za or steven@acufill.co.za